Multipass Printing : Single Extruder Multicolor 3D Printing

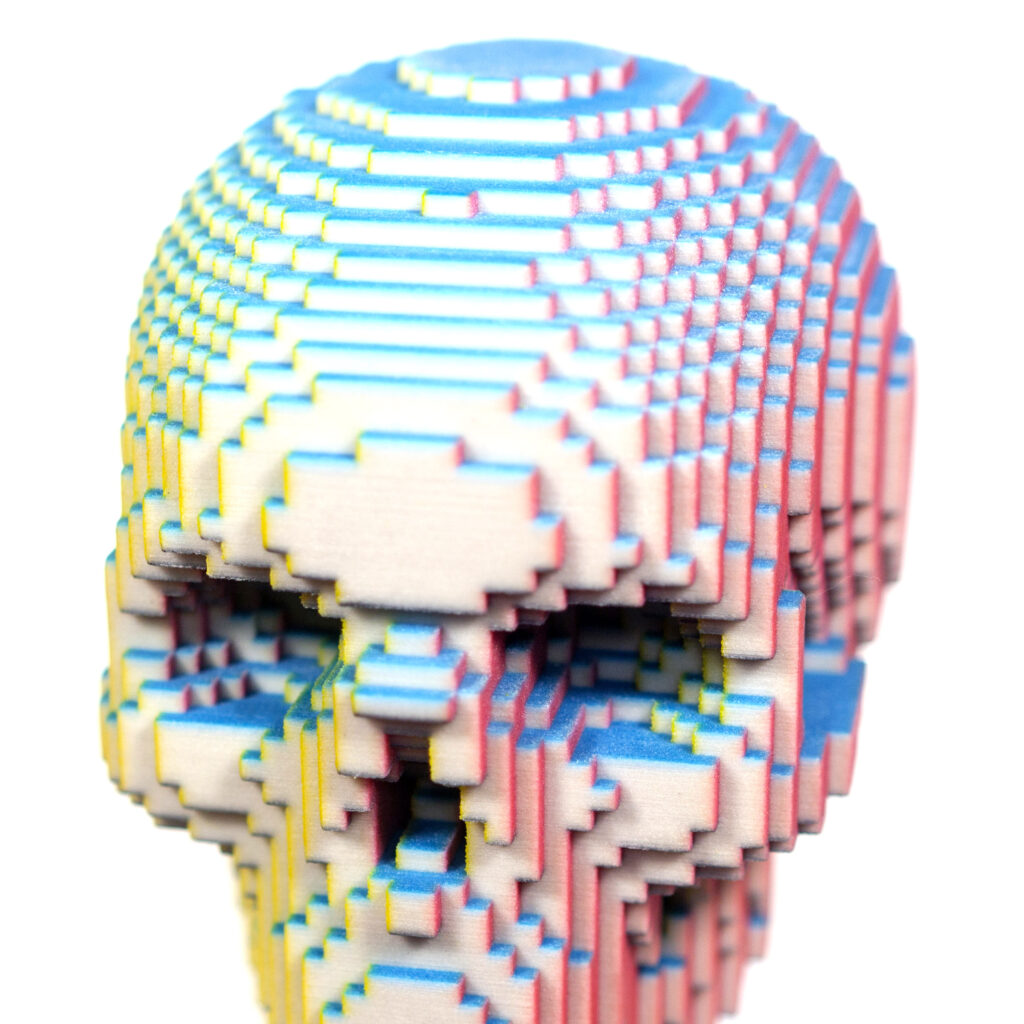

Multicolor 3D prints can add an extra level of interest to your 3D printed models, but it can also make the printing process more difficult. While 3D printers that can handle 2 or more materials are growing in number, they still tend to add complexity and increase the potential for failed prints and other problems. The good news is that there are still ways to get colorful prints off of a standard single extruder FDM/FFF 3D printer by using a technique I’ve dubbed Multipass Multicolor Printing.

Check out some videos I’ve made on the topic below to learn more :

Multipass Printing Playlist

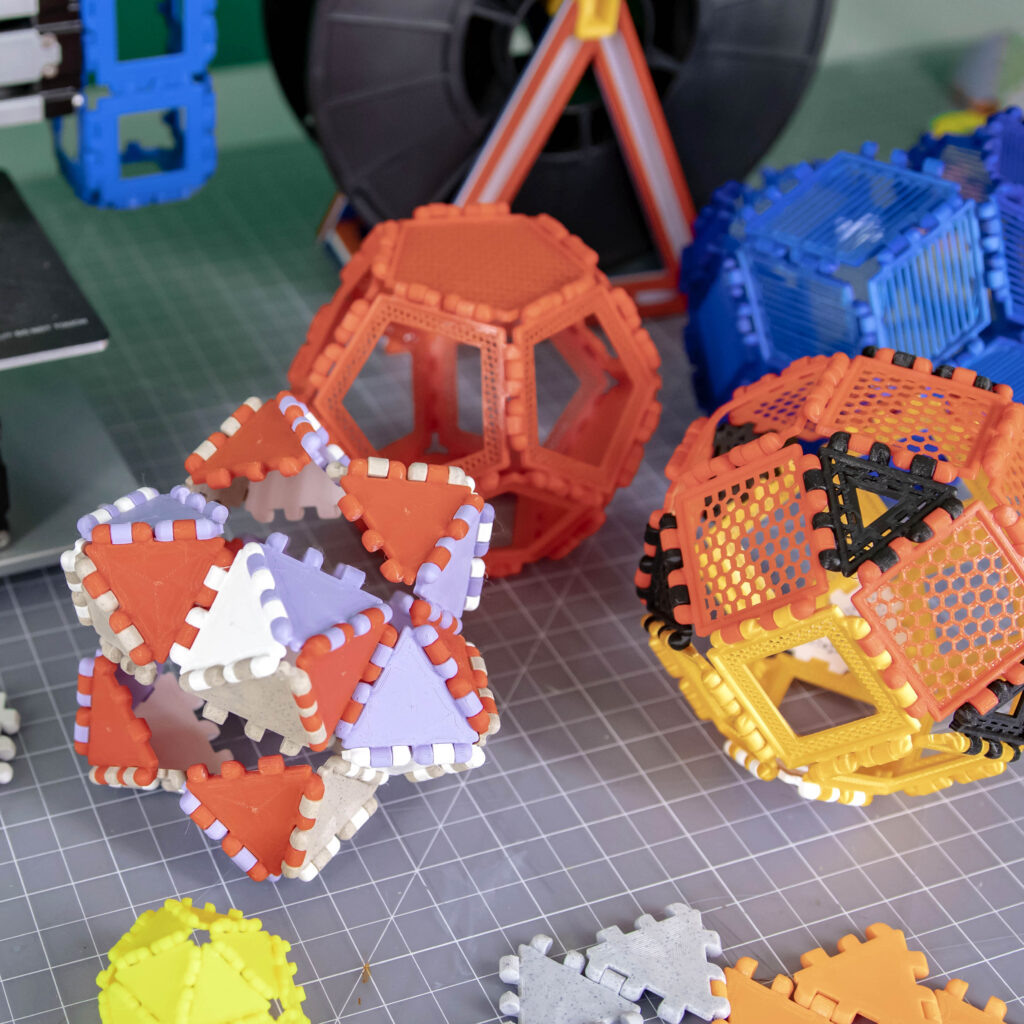

As it turns out, you can achieve multicolor graphics on prints by laying down one color at a time. It’s done by taking advantage of a slicer feature known as z-hop or retraction vertical lift. By having the printer nozzle lift up while traveling, it can pass over previous colors you’ve printed.

One of the main limiting factors is the shape of your hot end. A nozzle with a sharper point can more easily print right next to another color without smearing the plastic too much. That said, most standard FDM 3D printers can manage multipass printing to some extent!

The most simple way to get a multicolor face on the build surface is to separate a model into individual STL files for each color. How thick these first color layers can be may depend on your specific design and printer, but generally you can get away with 0.4mm tall parts. Just make sure the colors after the first print have a vertical z-hop equal to or greater than the highest point of the previous colors.

To step things up another level you can achieve more complex designs like gradients and multicolor on multiple faces with folding prints (See the third video in the playlist above)

Resources

Software

- Fusion 360 (free/paid)

- Cura (free)

- Simplify3D (paid)